Strongest for Weight

They have the best strength-to-weight ratio compared to other Aluminum casting parts. A density of only 2.7 g/cm³, aluminum delivers the strength families require without extra weight. The ultimate tensile strength of aluminum cast parts ranges from 70 to 700 MPa depending on the specific alloy and the casting process. In industries where every gram counts, such as aerospace and automotive, this distinctive characteristic is a huge advantage in cutting down the weight of the components that are required for performance and to save fuel.

Enhanced Corrosion Resistance

Aluminum is naturally corrosion resistant due to its ability to spontaneously form a thin layer of aluminum oxide which acts as a barrier to protect the underlying material degradation from atmosphere influences. This passive security makes die cast aluminum bonded components very valuable in applications pitched to unforgiving climate changes such as undercarriage parts and marine equipment and hardware that are tied in to sustain weathering and salty waters without more spending for care.

High Thermal Conductivity

Aluminum's thermal conductivity is significantly higher than that of many other metals, typically around 235 W/mK. This property is crucial for applications requiring efficient heat dissipation such as in automotive radiators, heat sinks in electronic components, and other cooling devices. Aluminum casting parts facilitate the rapid transfer of heat, aiding in maintaining optimal operational temperatures and improving the longevity and reliability of the components.

Efficient in Cost Management in Manufacturing

Lower Production Costs: Because aluminum is in such wide supply and is easy to cast, it is less expensive than overall production. Aluminum casting enables the production of highly complex shapes and dimensions that could be very expensive to achieve through other metalworking like forging or machining. The fact that near-net shapes can be cast (with reduced material waste and less secondary machining) goes some way to reducing production cost.

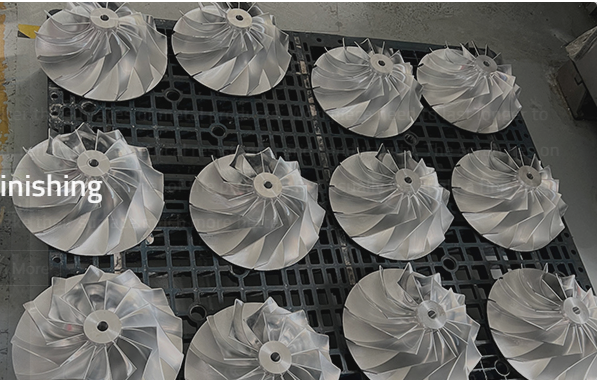

Machinability

Machinability/Finishing: It is approximately one-third the weight of steel, so parts made from it will also be much easier to machine and finish. It decreases the machining tools wear & tear and the time required to manufacturer the final parts. Moreover, the machinability of aluminum, along with its ability to create more intricate geometries that are often demanded in intricate assemblies.

Renewability and Sustainability

Aluminum recycling typically saves around 95% of the energy required to make new aluminum from bauxite ore and other raw materials. This energy savings are great examples for showing that using aluminum helps in making manufacturing much more environmentally friendly. These aluminum casting parts are all completely recyclable without compromise to their material properties, and this waste reduction approach can make it an eco-friendlier choice for industries that reciprocate the need to lessen their environmental impact.

Final Insights

Aluminum casting parts present a host of benefits which is why they are a popular choice across multiple industrial applications. These aluminum castings offer manufacturers the strategic advantage of saving weight yet adding strength, increasing corrosion resistance, managing thermal characteristics and, notably, the efficiency benefit of a low-cost, eco-friendly production process.